Mechanical Engineering in Medical Device Innovation

Mechanical engineering is a key player in creating new medical devices that save lives. This field works closely with the medical industry to build complex systems that work with the human body. Mechanical engineers use their knowledge of how things move and what they’re made of to help medical devices work better and be more reliable. They have led the way in making advanced medical robots, better prosthetic limbs, and materials that change to match what the body needs. They also work on making devices smaller, which leads to surgeries that are less harsh and opens up new ways to help patients. As new technologies emerge, mechanical engineers keep pushing healthcare forward, leading to better health outcomes and pushing the limits of medical treatments.

For example, mechanical engineers have been involved in the development of the da Vinci Surgical System, a robotic platform that allows surgeons to perform complex procedures with more precision and control. This innovation has made surgeries less invasive, reduced recovery times, and improved patient experiences. Mechanical engineers’ contributions to medical device innovation are essential for the continuous improvement of healthcare.

The Role of Biomechanics

Biomechanics is crucial for creating and improving medical devices. It makes sure these devices work well with our bodies, keeping us safe. Engineers use science to understand how these devices will act inside the body. This is key to coming up with new, smart solutions that meet our body’s needs.

For example, they use computer programs to test how a device will perform, which helps them see where it might break or have problems. This information is very important for making the device better, more functional, and safer. Also, using biomechanical information helps make devices that are just right for each person’s unique body, which is a big step forward in making medicine more personal.

Here’s why this matters: When medical devices work in harmony with our bodies, treatments can be more successful. Imagine a knee replacement that’s designed just for your body’s shape and movement – it’s likely to work better and feel more natural. That’s the kind of progress biomechanics helps us achieve.

It’s like having a tailor for your medical needs, ensuring everything fits you perfectly. This is not only exciting for patients but also for doctors and engineers who want to offer the best care possible.

Medical Robotics Breakthroughs

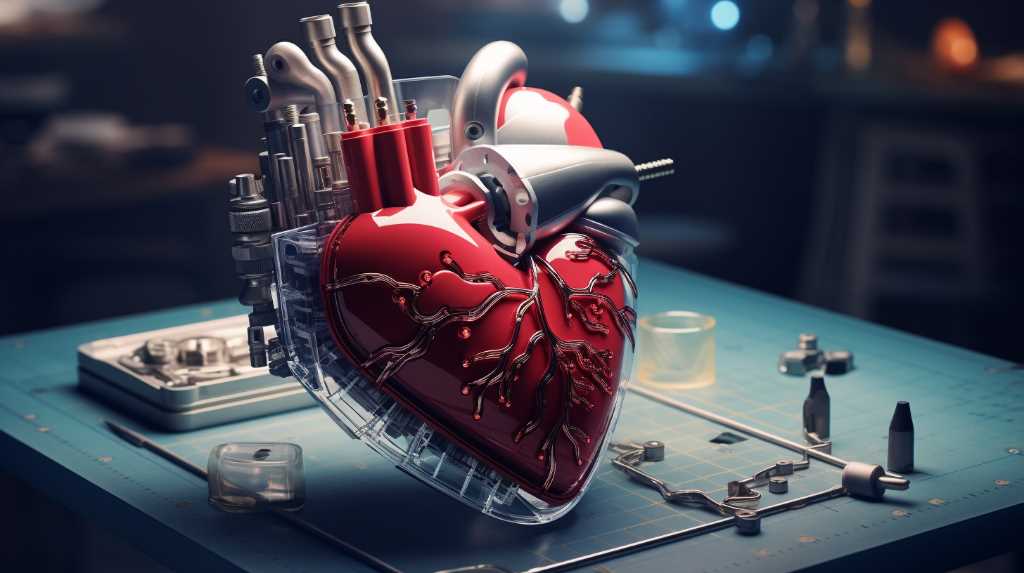

In the field of medical device engineering, one of the most important recent advancements is the creation of advanced medical robots. These robots are changing the way doctors perform surgeries and take care of patients.

For example, medical robots can move in precise and delicate ways that allow doctors to operate on patients without making large cuts. This means patients can heal faster and are less likely to have problems after surgery. A well-known example of this technology is the da Vinci Surgical System, which has robotic arms that surgeons control to operate with great accuracy and a 3D camera that helps them see clearly inside the patient’s body.

Furthermore, engineers are making robotic limbs and supportive frames for people who have lost limbs or can’t walk. These robotic aids use new materials and sensors to help people move more naturally. Engineers work hard to improve the parts that make robots move, the programs that control them, and the ways robots can send back touch sensations to the user.

This work is leading to better ways to help patients recover and get diagnosed, focusing on care that really fits each patient’s needs and leads to better health after treatment.

Advancements in Prosthetics

The world of prosthetic limbs is changing fast, thanks to the mix of mechanical engineering and robot technology. These new prosthetics work better and are more comfortable for users. They use smart programs and precise machines to let people with amputations move almost like they would with natural limbs.

Materials are also key—they’re now strong but light, so they last long without making it hard to move. For example, prosthetic knees and ankles can now think on their feet, adjusting to different surfaces and walking speeds to help users walk smoothly.

Plus, there’s a new method called osseointegration that connects the limb straight to the bone, getting rid of pain from traditional sockets and making it feel more natural.

All these changes show how important mechanical engineering is in making life better for people missing limbs.

Smart Materials Integration

The field of prosthetics is getting better thanks to a mix of mechanical engineering and robotics. Now, the addition of smart materials is changing how medical devices work, making them more useful and flexible. Smart materials can change how they act when things like temperature, pressure, or electrical signals change. This means we can make devices that adjust themselves to what a patient needs right away.

For example, materials that remember their shape, ceramics that generate electricity when pressed, and plastics that are safe for the body have led to new types of bone implants that fit themselves, drug delivery systems that are very accurate, and sensors that react quickly to biological signals.

When it comes to creating these materials, the challenge is to design and build them very precisely so they work well and are safe to put in the body. Because of this, mechanical engineers now need to know a lot about materials too. They have to make sure that these new medical devices do their job well and are safe for people to use in real-life medical settings.

Miniaturization of Devices

Making medical devices smaller is a big step forward. It lets us make advanced tools that can work inside the human body without causing much harm, and they’re very precise. Engineers use special techniques to make parts very small. They need to know a lot about how materials act when they’re tiny. These small devices often use MEMS, which are tiny moving parts and electronics together, to do things that weren’t possible in such small devices before.

Mechanical engineers are leading this change. They design complex devices that can handle being inside the human body and still work well. When devices get smaller, problems like getting rid of heat, making sure materials are safe for the body, and moving parts accurately get tougher. Engineers must be creative and skilled to solve these problems.

Because of making things smaller, medical treatments are becoming less harsh and more specific, which helps patients get better faster. For example, a tiny camera pill that patients can swallow allows doctors to see inside the body without surgery. This is less painful and safer for the patient. It also means they can leave the hospital sooner and recover at home.

Conclusion

Mechanical engineering is crucial for the progress in medical devices. It’s at the heart of creating new technologies in areas like biomechanics, medical robots, artificial limbs, advanced materials that respond to their environment, and making devices smaller. These improvements are important because they make treatments better and help patients live better lives.

When mechanical engineering works together with medical science, the result is new, efficient, and tailored tools for health care. This teamwork is changing the way we look after patients, thanks to creative solutions and working across different fields.

For example, medical robots designed by mechanical engineers are now performing precise surgeries, which were once only possible by human hands. Prosthetics have become smarter, with materials that adapt to the user’s movements, making life easier for amputees.

This shows how essential mechanical engineering is in making health care better for everyone.